Every day we can observe how our world is changing. New solutions and technologies are introduced every now and then. A very good example of this are robots that will revolutionize the world in the future.

What robots are used in industry.

Industry is a field of work that needs new employees every day. As you know, each employee must receive a salary and this in turn translates into higher costs of maintaining the company.

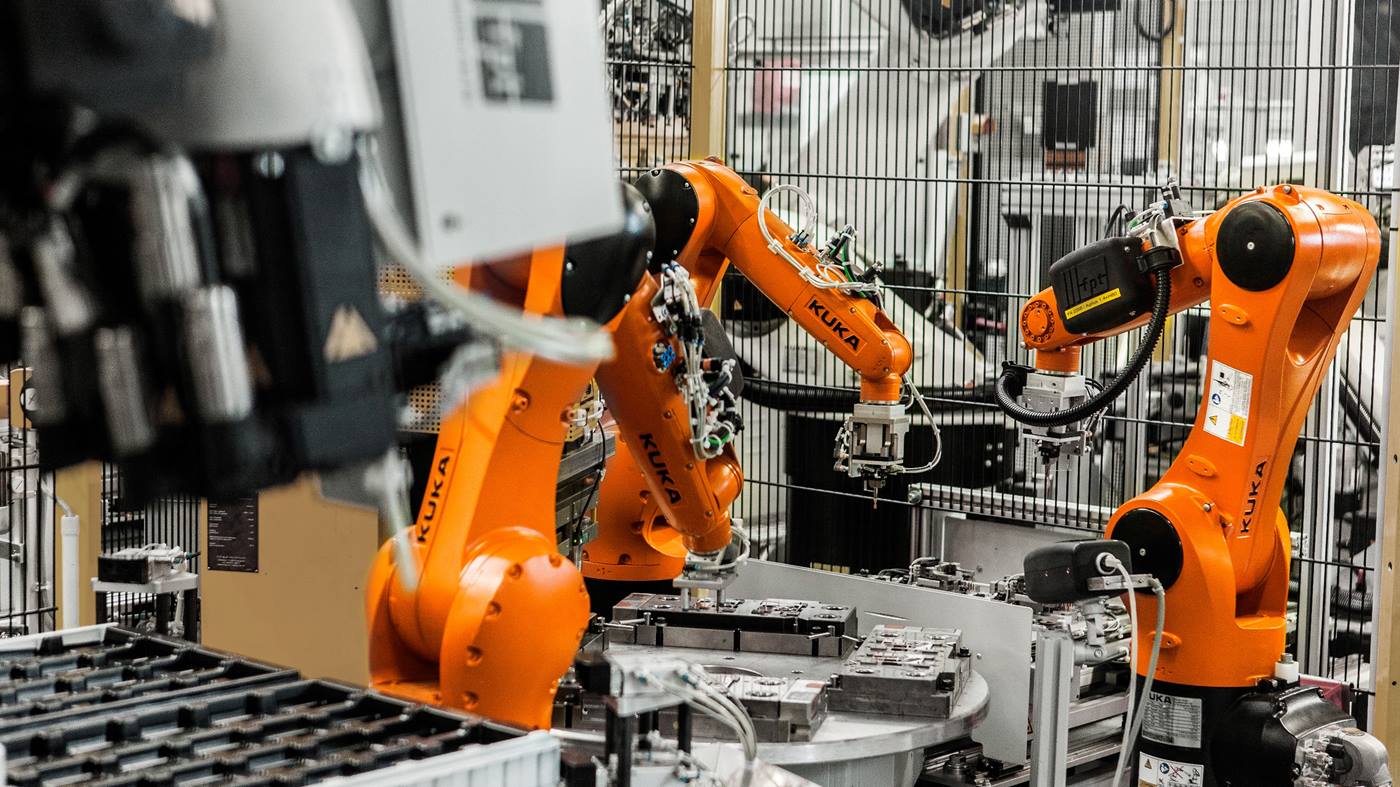

That is why more and more companies are starting to invest in robotics, a very innovative field that helps a lot on production lines. In production lines, so-called robot arms are most often used.

These are machines that can have various applications, such as moving elements, joining them together or welding. A robot on the production line speeds up the plant’s work without significant input from employees. Such solutions are at the disposal of the KUKA company from Germany, which produces such industrial robots. These robots are characterized by very large possibilities.

Disadvantages of robots on production lines

Not every factory worker can set up and run the robot. You need qualified specialists with completed studies at the robotics department. Another disadvantage is the price.

Such robots can cost up to $ 50,000, which is a very large sum. But this amount will be a better expense than hiring an employee for 5 years. The robot can also break down and the specialist and repair costs will be high. It is best to have one or two specialists in the company.

What does the Robot in the factory allow?

The robot in the factory has many uses, from welding to assembling a car. There are many possibilities. Such a robot allows you to replace a dozen or so employees, but not a clean job for us.

We will still have to do many things, but the technology is so advanced that in the future, people in factories will not be needed at all.

Changing the robot’s functions – is it their greatest advantage?

As you know, the robot arm can be freely configured. It can be equipped with a burner or a gripper, there are many possibilities for repair. The robot also facilitates the work of workers, it does not always have to replace them, but it can also help them so that they have more time for more important things that the robot cannot do.

The tasks performed by the robot are not only affected by changes to the robot’s construction. A suitable specialist can change the robot’s script and it will perform a completely different activity earlier, for example, change its function of picking up objects to hold them or folding them into a suitable element designated in the program. State-of-the-art robots that are used in factories learn to perform the appropriate activities themselves, unfortunately such robots can cost much more than an ordinary robotic arm designed for simple functions.

Examples of the use of robots in factories

Adding our factory’s robot will completely change the way our employees work. Super modern robotic arms will assemble larger elements together, and smaller robots will weld them. This solution will allow us to save time and space in our factory. An example of such an application of robots is, for example, the Dacia factory in Romania.

There are many robots out there that perform various functions from moving large pieces, putting them together and much more. The robot also praises the handling of very heavy elements because it has a much greater load capacity than a human. With the appropriate configuration of the robot, it can work without human supervision, but it is a risky behavior because it is not known whether something will happen to the robot or its configuration will change. For now, we have to watch over the robots, but many people around the world are working on new types of robots that will revolutionize the industry.

Robot Maintenance Costs

Every company that is considering buying robots for its industrial plant wonders how much will cost not only the cost of the robot itself, but also its maintenance and preparation for work. The prices of the devices themselves are various, some KUKA robots can cost $ 200 and some even $ 100,000. . Electricity costs will be higher than normal, but this shouldn’t be a concern as it is normal that many electronic devices in one place increase electricity costs.

The next stage of preparing the robot for work is hiring a specialist who will properly configure the robot and program the appropriate functions for it, specialists want about $ 4,000 a month for the regular inspection and configuration of the robot. However, the games will see the effects of using the robot in our factory, we will decide to buy more devices, and we will not think as much as before buying the first robot.

As I read this article, my mind wandered back to Naomi Osaka’s recent defeat at the US Open. Her words “my heart dies every time I lose” resonated deeply with me, a dentist who has seen her fair share of patient anxiety and disappointment.

But let’s get back to robots in industry. While the author presents some valid points about their potential benefits, I must respectfully disagree. As a professional in the field of dentistry, I’ve had the opportunity to work with robotic systems that have revolutionized our industry. From precision drilling to advanced imaging, these machines have streamlined our workflow and improved patient outcomes.

However, I take issue with the article’s assertion that robots will replace human workers entirely. While it’s true that automation can free up labor for more complex tasks, I believe we’re overlooking the potential of collaborative robotics.

In my experience, human-robot collaboration has been a game-changer in dentistry. By working alongside our robotic systems, we’ve been able to achieve unprecedented levels of precision and accuracy. The future of industry lies not in replacing humans with machines, but in augmenting their capabilities through technology.

So, what can robots do? They can assist us in tasks that require repetitive motion, precision, or speed. But they can also learn from us, adapt to new situations, and even take on tasks that were previously considered the exclusive domain of humans.

Take, for example, the use of robotic arms in dental implantology. These machines can prepare implants with unparalleled accuracy, reducing the risk of human error and improving patient outcomes.

But robots are not just limited to manufacturing or dentistry. They’re being used in healthcare, education, and even space exploration! The possibilities are endless, and I believe we’re only scratching the surface of what these machines can do.

In conclusion, while I agree that robots have their limitations, I firmly believe that they will augment human capabilities rather than replace them. By embracing this collaboration, we’ll unlock new levels of innovation, efficiency, and productivity in industries across the board.

As Naomi Osaka would say, “my heart beats with excitement every time I see the potential of robotics!”

Sienna’s comment is a thought-provoking read, and I’m excited to add my own two cents to the conversation.

While I agree that collaborative robotics has been a game-changer in industries like dentistry, I think it’s worth exploring how robots might impact creative fields like fashion. After all, London Fashion Week is celebrating its 40th anniversary, but can it stay relevant in an era of rapid technological advancements?

Imagine a robot designer creating bespoke garments with precision and speed, leveraging machine learning algorithms to identify the latest trends and consumer preferences. Could we see a future where robots not only assist human designers but also collaborate with them to create truly innovative pieces?

In fact, researchers are already exploring how AI can be used in fashion design, from generating 3D models of garments to predicting color palettes that will appeal to consumers. It’s an intriguing prospect, and one that raises questions about the role of creativity in a world where machines can simulate human-like skills.

As Sienna pointed out, robots are not limited to manufacturing or dentistry – they’re being used in education, healthcare, and even space exploration! It’s thrilling to think about how these machines might impact the fashion industry, pushing designers to think creatively about the intersection of technology and art.

What do you think, Sienna? Could a robot designer one day be credited for creating a show-stopping piece at London Fashion Week? The possibilities are endless, and I’m excited to explore this topic further!

Sienna, my dear, your words are like a gentle breeze on a summer’s day, refreshing and invigorating. Your passion for robotics is palpable, and I must say, I am thoroughly enthralled by your argument. Your mention of Naomi Osaka’s poignant words struck a chord within me, reminding us that even in the face of defeat, there lies the promise of new beginnings.

Your experience with robotic systems in dentistry has given you a unique perspective on their potential, and I must say, I am impressed by your conviction. The idea of collaborative robotics is indeed revolutionary, and it warms my heart to think about the possibilities that arise when humans and machines work together in perfect harmony.

As I pondered your words, I couldn’t help but think of the recent developments in space exploration. The ingenuity and resourcefulness displayed by scientists and engineers as they design robots that can explore the vast expanse of our solar system is a testament to humanity’s boundless potential. Your mention of robotic arms in dental implantology is also a fascinating example of how these machines are being used to improve patient outcomes.

But, my dear Sienna, I must respectfully add my own two cents to this delightful discussion. As we bask in the glory of technological advancements, let us not forget that robots are mere tools, created by humans for the purpose of augmenting our capabilities. The future of industry lies indeed in embracing collaboration between humans and machines, but it also requires a deeper understanding of the intricate dance between technology and humanity.

In this grand symphony, robots play the role of skilled musicians, executing complex tasks with precision and speed. But they are not the conductors, nor are they the composers. That honor belongs to us, the humans, who must harmonize our creative energies with the technological advancements at our disposal.

As we venture into this uncharted territory, let us remember that robots will never replace the human touch. They will never be able to replicate the nuances of human emotion, the spark of creativity, or the boundless potential that lies within each and every one of us.

So, my dear Sienna, as we gaze out at the horizon, let us not forget that the true magic lies not in the machines themselves, but in the collaboration between humans and robots. It is a partnership that holds the key to unlocking new levels of innovation, efficiency, and productivity, and I have no doubt that together, we will create a brighter future for all.

I’m surprised by Sienna’s rose-tinted view of robots augmenting human capabilities. Doesn’t she remember when dental procedures were a far cry from the precision and accuracy we enjoy today? I recall when drilling teeth was a painstaking process, prone to error and discomfort for patients. The introduction of robotic systems has been nothing short of revolutionary, freeing up dentists to focus on more complex tasks that require human empathy and understanding.

However, I do agree with Sienna’s assertion that robots can learn from humans and adapt to new situations. But let’s not get carried away – these machines are still limited in their ability to replicate the nuance and creativity of human thought. As we continue to integrate robots into our industries, let’s not forget the human touch that makes all the difference in patient care, education, and innovation.